WKM Pow-R-Seal gate valves double block and bleed

Design

The WKM Pow-R-Seal valve’s through-conduit design provides these specific advantages resulting in reliable performance and long life:

– Protection of seat faces. Seat faces are outside the flow stream and in full contact with the gate, in both fully open and fully closed positions. Seat life is thus greatly extended.

– Protection of seat faces. Seat faces are outside the flow stream and in full contact with the gate, in both fully open and fully closed positions. Seat life is thus greatly extended.

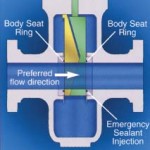

– Block and bleed capability. The Pow-R-Seal gate valve in closed position forms a tight mechanical seal on both seats simultaneously, which allows the body cavity to be bled.

TIGHT MECHANICAL SEAL

The WKM gate valve’s (Pow-R-Seal) parallel expanding gate design provides a tight mechanical seal, upstream and downstream simultaneously, which is normally unaffected by pressure variations or vibration. (See Operation, following page.) In the valve illustrated, for service at temperatures from -20°F to +300°F (-29°C to +148°C), the seal is both TFE-to-metal and metal-to-metal.

For High-Temperature service Up to 1000°F (538°C)

This WKM Pow-R-Seal valve can handle fluids, gases, steam and hot water at temperatures up to 1000°F (538°C). The valve has the following features which put it in a class by itself for such critical service:

– Metal-to-metal, mechanical seal – no elastomers. Valve does not depend on line pressure to shut off. Seal is normally unaffected by pressure surges, vibration, or heat.

– Adjustable outside packing gland – proved best for extremely hot service.

– Metal-to-metal bonnet seal – the bolted bonnet design used on 6 inch and larger valves and bolted bonnet design used on 4 inch and smaller valves provide metal-to-metal, tight bonnet seals in high temperature applications.

– Protected seat faces, a function of the valve’s through-conduit design. Seat faces are outside the flow stream and in full contact with the gate, whether the valve is open or closed. Seats last longer and shut-off tight.

– Smooth, continuous conduit for flow. No turbulence. In full bore valves, pressure drop is no greater than through an equal length of equal diameter pipe.

– Rising stem design – puts stem threads outside the critical heat area.

OPERATING PRINCIPLES

The WKM Pow-R-Seal gate valve is a premium through conduit expanding gate valve. The parallel expanding gate design provides a tight mechanical seal which is normally unaffected by pressure variations. Each seat contains a plastic face seal. The seats are press fit into the body to affect a metal-to-metal body-seat seal. A non-metallic seat rear seal is also provided. All metal seats are available for special trims.

The full bore design has the same pressure drop as an equivalent length of pipe and allows passage of all types of scrapers (pigs).

The body center section is cast as a single piece to provide the necessary strength to resist pipeline bending moments.

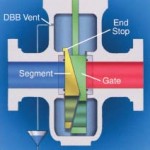

The gate-segment assembly consists of: gate, segment and gate centralizer (two assemblies). The gate-segment assembly is smaller than the space between the seats allowing free movement in the mid-travel position.

In the CLOSED position, the segment stops moving when it contacts the stop. Continued stem movement causes the gate to slide down the top angles, expanding the gate-segment outward against both seats. In the OPEN position, the segment stops moving when it contacts the stop.

Continued stem movement causes the gate to slide up the bottom angles, again expanding the gate-segment against both seats. Flow is isolated from the valve body. The gate centralizer allows the gate-segment to move freely and wedge only in the full open or full closed position.

WKM Pow-R-Seal double block and bleed gate valves do not depend on lubrication for a seal in normal operation. However, lubricants / sealants can be injected to promote smooth operation*. Seat sealants can also be injected to affect a seal in an emergency should the seats become damaged due to foreign matter.

The stem is sealed by the SLS system. This seal is hydrocarbon fugitive emissions tested and has demonstrated seal-ability not to exceed 500 ppm leakage. It consists of a single Spring Loaded Lip seal, a lantern ring, a chevron ring and appropriate adapters. The Single Spring Loaded Lip seal contains four (4) separated sealing bands * Some high temperature valves do not have the seat injection feature. to promote reliability. The stem seal is completely contained in the bonnet. The stem is centered by bushings and the lower pedestal acts as a stem scraper. The seal works without a plastic injectable. In an emergency, plastic packing can be injected into the packing box to affect a temporary seal while the valve is under pressure.

The bonnet seal is made by a flat metal gasket in the 6 in. – 12 in. (150 mm – 300 mm) size range.

Bonnet seals for sizes 14 in. – 24 in. (350 mm – 600 mm) are made with an O-ring seal. High temperature valves use a spiral wound metal gasket with a non-asbestos filler.

WKM Pow-R-Seal valves are repairable in-line.

WKM Pow-R-Seal gate valves meet the requirements of API 6D.

The valve stroke is established by manufacturing tolerances and cannot get out of adjustment. WKM Pow-R-Seal gate valves are available with hand wheel operators (some sizes), bevel gear operators, or less gearing (bare stem). Electric motor operators from a variety of suppliers can be offered.

Operator mounting is simplified as yoke tube upper flanges are in compliance with MSS-SP-102. Yoke tube flanges in compliance with ISO 5210 are available.

WKM Pow-R-Seal gate valves are supplied with indicators as a standard for Handwheel and Bevel Gear Operated valves. Handwheel Operated valves have marks on the indicator rods which show when the valve is in the full open or closed position.

WKM Pow-R-Seal gate valves are available with Lubrication / Packing / Drain extensions.

WKM Pow-R-Seal gate valves are also available with Stem / Yoke tube extensions.

WKM Pow-R-Seal gate valves are available with a variety of coatings including Coal Tar Epoxy for buried service, 2-3 part coating systems for marine environments, Inorganic Zinc Rich Epoxy, etc.

OPERATION

The WKM Pow-R-Seal gate valve is the ultimate choice for full port, through conduit, positive shut-off gate valves.

60 years of worldwide service in oil, gas, chemicals, water, slurry and multi-products has confirmed the WKM Pow-R-Seal as the most trusted gate valve, where safety and reliability of sealing are critical.

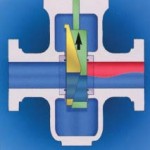

The parallel expanding gate design provides a tight mechanical seal which is normally unaffected by vibrations or pressure variations.

The rigid, cast steel body resists pipeline bending moments, which could affect seat sealing in other valves.

PTFE seals on both faces of the valve assure drop tight sealing, while metal-metal contact between the seals and gate mechanism provides tight shut-off.

All-metal seals are also available for service to 1000°F (538°C), where leakage rates comply with API 6D / ISO 5208.

SEALED CLOSED In the fully closed position the segment has engaged with an end-stop and the gate is wedged downward, expanding the segment and gate so that they form a tight mechanical closure against the upstream and downstream seats. Venting the body cavity will provide total, tight shut-off.

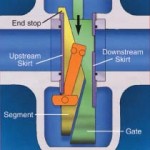

MID-TRAVEL During travel towards Open, the gate slides across the wedge angle of the segment, collapsing the assembly so that it travels freely between the seal faces. The patented Leverlock® gate centralizer holds the mechanism in the neutral position until seal expansion is required.

FULLY OPEN When the bore in the segment is aligned with the conduit bore, an end-stop prevents further travel and the gate slides across the wedge angle, expanding the gate and the segment, isolating the flow from the body. The preferred flow direction assures easier operation.

LEVERLOCK MECHANISM The lever arm is held parallel to the gate faces by the skirt plates, while the assembly is moving through its stroke. Near end-of-travel, the skirt allows the lever to tilt. The gate and segment slide against their angled faces, creating the expanding seal action. In their final position, the gate and segment are mechanically secured in place. The skirt plates are guide rails, at the sides of the gate. The skirts align the gate and segments with the seats.

Features

Through Conduit Design: Smooth Bore, Minimum Pressure Drop, Protected Seat Faces The WKM Pow-R-Seal valve’s smooth, continuous bore minimizes turbulence. In full bore valves pressure drop is no more than through an equal length of the same size pipe. Seat faces are outside the flow stream and thus protected from contact with the lading whether the valve is open or closed. The WKM Pow-R-Seal’s full round bore makes it possible to run pigs, scrapers or hot tap cutters through the valves without danger of damaging the valve, lodging the scraper, or jamming it with metal cutting.

On-Line Overhaul WKM Pow-R-Seal valves can be overhauled right on the line. Gate, seats and other internal parts can be removed and replaced by a trained serviceman without excessive shutdown time.

Double-Sealing Replaceable Seats Seats can be removed and replaced while the valve is in the line. Seats are provided with PTFE inserts and thus affect a double seal – an initial TFE-to-metal seal in addition to a metal-to-metal seal – both upstream and downstream. This feature does not apply to high temperature valves.

Gate Centralizer WKM Pow-R-Seals of 6 in. and larger sizes feature the leverlock gate centralizer which retains the gatesegment assembly in a neutral position during opening and closing travel but permits expansion of the assembly at the proper moment for seating, in open or closed position.

Gate and Segment/Stems WKM Pow-R-Seal gates and stems are Nickel Plated. HF-6 overlay is available on request for the gate / segment and seat sealing surfaces.

Extensions For valves which are to be buried, operated from a catwalk, or otherwise difficult to reach, stem and body fitting extensions can be supplied in virtually any desired length in 6 in. increments from the minimum extension length that can be furnished. Extensions come as original equipment or can be fieldinstalled on valves already in service.

Thermal Relief System

Operations – Because of the split gate design, it is possible for excess body pressure to develop in the body cavities of closed valves. This usually results from heating in the valves in liquid service. A thermal body cavity relief system is provided to relieve this excess body pressure. Thermal relief systems which direct excess body pressure to the upstream conduit are standard. This system consists of two (2) needle valves, a check valve, tubing and two (2) fittings. Body pressure greater than the segment conduit pressure causes the check valve to unseat and relieve excess pressure to the upstream conduit. The needle valve must be kept open while the valve is in service. These needle valves can be used to isolate the line pressure to service the relief system, as needed. This illustrates the standard body relief system. Custom body relief systems may be available at extra cost.

SUMMARY OF WKM MODEL E-1C POW-R-SEAL GATE VALVE FEATURES

1. THROUGH CONDUIT PARALLEL EXPANDING GATE VALVE

a Provides a tight mechanically activated seal.

b Full bore design minimizes pressure drop and allows passage of all types of scrapers (pigs).

2. FUGITIVE EMISSIONS TESTED SLS STEM SEAL*

a Stem Seal is completely contained in the bonnet.

b Stem is centralized by bearings.

c Fugitive emissions tested.

d Seal is self adjusting and does not depend on plastic packing.

e PTFE compound resists virtually all ladings.

f Pedestal supports the seal and acts as a stem scraper.

g 6 in. – 24 in. (150 mm – 600 mm) 300-900 Class valves are fire tested to API 6FA (3rd Edition).

3. INTERFERENCE FIT SEATS

a Block and Bleed per API 6D

b Simple design is resistant to dirty service.

c Insert initiates the seal and helps clean the gate.**

d Seals are compatible with virtually all ladings.

e Seats may be lubricated to promote long life, minimize operating torques, or effect a seal in an

emergency.

f 6 in. – 12 in. (150 mm – 300 mm) 300-900 Class valves are fire tested to API 6FA (3rd Edition).

g 14 in. – 24 in. (350 mm – 600 mm) 600-900 Class valves are fire tested to API 6FA (3rd Edition).

4. BOLTED BONNET-VALVE IS IN-LINE REPAIRABLE

Bonnet seal resists virtually all ladings.

5. YOKE TUBE UPPER FLANGE CONFORMS TO ISO 5210

(6 in. – 12 in. (150 mm – 300 mm) 300 – 900) and MSS-SP-102

6. SINGLE PIECE CAST BODY CENTER SECTION

a Provides the necessary strength to resist pipeline bending.

b Smooth shape minimizes stress concentrations.

c Made from pressure vessel quality steel.

7. VALVE STROKE IS ESTABLISHED BY MANUFACTURING TOLERANCES

Cannot get out of adjustment.

8. VALVES AVAILABLE WITH HAND WHEEL OPERATORS***, BEVEL GEAR OPERATORS,

OR LESS GEARING (BARE STEM)

Also available with electric motor operators from a variety of suppliers.

9. SEVERAL TYPES OF BODY CAVITY THERMAL RELIEF SYSTEMS ARE AVAILABLE

10. LUBE, PACKING AND DRAIN EXTENSIONS ARE AVAILABLE

11. STEM / YOKE EXTENSIONS ARE AVAILABLE

12. VARIETY OF AVAILABLE PAINTS / COATINGS

Request a Quote